Our Solutions

will make the difference

Wondering why you should source your next automation solution from Pharmabotix – rather than old established suppliers?

Our solutions convince through innovation, highly compact design, and intuitive use. To provide our customers with high-quality service and automation solutions at all times, all our internal processes are designed strictly in accordance with GMP / GAMP5 and documented accordingly in our quality management system in accordance with ISO9001:2015. We will make the difference in your production – contact us now!

Services

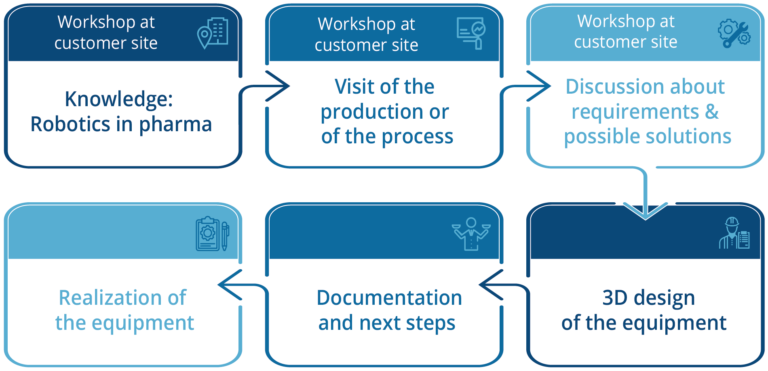

A successful project requires a sound base, this is why Pharmabotix sets high value on the initial project steps, conceptual design, risk assessment as well as appropriate feasibility studies / mockups and basic design. Working through these first steps carefully and to the full extent is an essential pre-requisite for success.

- Machine building from the design concept to the turnkey solution

- Inhouse engineering, software, assembly

- Mockups and feasibility studies

Consulting & Workshops

Are you seeking experts to support your robotics and automation projects? Do you want to better understand the possibilities of modern robotics? Our team provides comprehensive guidance on integrating robotics and AGVs into existing production environments and new construction projects. We even assist with planning your building layout to ensure optimal alignment with your automation goals. With our Workshop & Engineering Package, we tailor solutions specifically to your processes.

- Consulting for existing productions

- Consulting for greenfield projects

- Production walk through and opportunity analysis

- On-site workshop

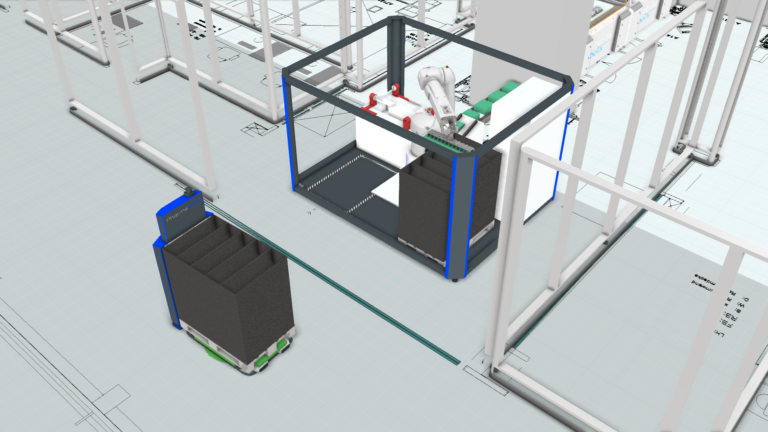

Simulations

Do you need confirmation that our robotics solutions can meet your cycle time requirements? Or do you need visualization to convince your senior management of an idea? Our simulations, based on your production layouts, offer the clarity and planning security you need. We are skilled at creating simulations based on your production layouts.

- Simulations of robot solutions

- Simulations of mobile robots & AGVs

- Integration of the customer layout

- Cycle time analysis & accessibility check

- Calculation of the number of robots required

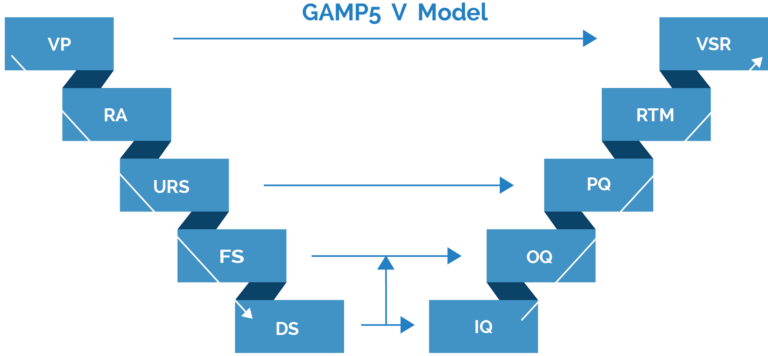

Regulatory Environment

Pharmabotix adheres to current GMP and GAMP guidelines, recognizing the importance of documentation, validation, and qualification alongside the construction of the facility itself. This ensures that our facilities meet the needs of our customers and comply with regulatory requirements. Our internal processes are consistently structured according to the GAMP 5 model.

- Traceability matrix

- Risk analyses & FMEA

- Specifications

- Design documents

- Qualification & validation

- CE conformity assessments

Mechanical engineering and construction

From individual components to complete systems, we meticulously design tailored solutions. Our experienced engineers specialize in finding the right solution for every challenge. Whether it’s an airsampler, reactor valves, or other specialized solutions, we’re here to help. Thanks to state-of-the-art rapid prototyping technology, we can test and optimize our solutions cost-effectively.

- Construction of individual assemblies through to complete systems

- Construction of special solutions beyond robotics

- Rapid prototyping (3D printing, laser cutting, etc.)

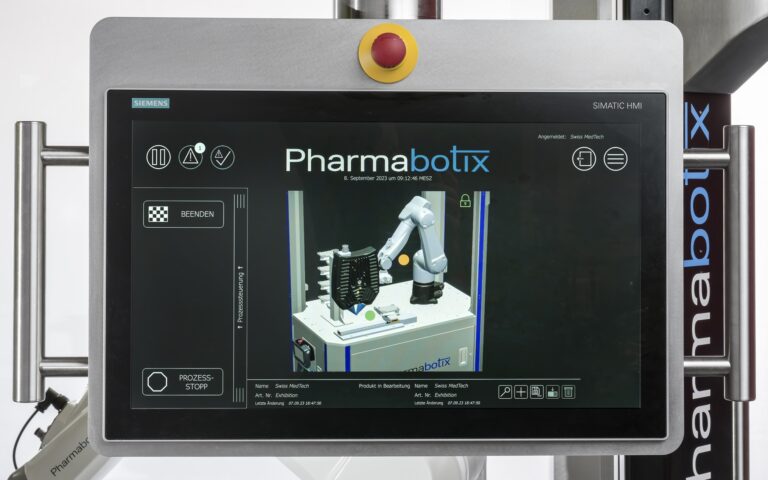

Software engineering

Our software team possesses extensive expertise in Siemens controls. We prioritize user-friendliness and utilize the latest UNIFIED HMI generation. By fully integrating all devices into Siemens controls, including cameras, sensors, and robots, we ensure smooth operation of your systems. We also offer connectivity to control systems using OPC UA.

- Siemens Unified HMI including all relevant GMP Features

- Integrated motion & safety

- Interfaces to devices (Profinet, I/O Link, etc.)

- Interfaces to control systems via e.g. OPC UA

Control engineering

From creating electrical schematics to assembling control cabinets, you’re in good hands with Pharmabotix. We use Solidworks Electrical Software to ensure the highest quality and efficiency in our electrical schematics.

- Creation of electrical diagrams

- Dimensioning of electrical components

- Control cabinet assembly & wiring

Robotics

We rigorously apply the highest quality standards to robots – which is why we use the well-known Stäubli robots, among others like ABB, Fanuc, Kuka, Denso or Universal Robots. Stäubli Robotics is the market leader in cleanroom robots and stericlean robots for pharmaceutical and aseptic solutions. Stäubli’s stericlean robots can be decontaminated with hydrogen peroxide (H2O2) and are therefore ideally suited for use in isolators. Other robot brands can also be used upon customer request – based on our experience and knowledge, we will always suggest the optimal solution.

Stäubli 6 Axis Robot

Reach: 515mm – 2594 mm

Maximum payload: 2.3 kg – 150kg

Cleanroom class up to GMP A / Fully H₂O₂ resistant

Stäubli Scara Robot

Reach: 460 mm-1000 mm

Maximum payload: 8.4kg

Cleanroom class up to GMP A / Fully H₂O₂ resistant

- Handling Applications

- Packaging and palletizing

- Robotics in aseptic/sterile environments

- Liquid Handling